Jun 30, 2011 0

Smarter Manufacturing?

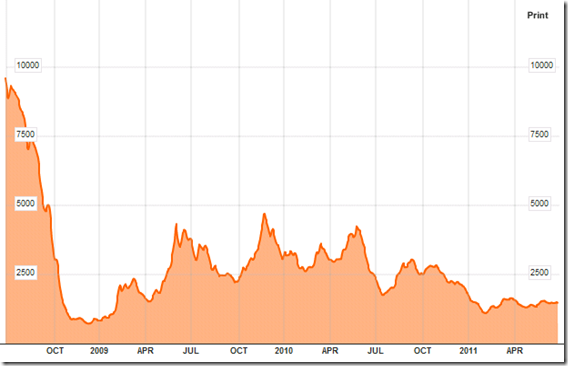

In an earlier post, I blogged about the Baltic Dry Index as a good indicator of economic activity (Read it here: Ready for a recession?)

Even if we were to magically start moving in the Baltic Dry Index in a positive direction which would be a tremendous relief for everyone (but remember – *magically*), the US treasury and the Federal Reserve would continue to devalue the US dollar for two practical reasons:

1) Repay outstanding debts with a depreciated currency. This is really quid pro quo with some of the trading partners of the US against whom the US has been running trade deficits for the better part of a decade. The whole point of trade is not for one side of the equation to accumulate a lot of paper currency but to reciprocate in buying the origin country’s exports.

2) Make US exports competitive with other countries and reignite production/manufacturing stateside.

In fact, if the US (and World) economy were to recover some what, the above two agencies would devalue the US dollar with a vengeance.

This sort of policy, if successful, would mean a repatriation of some of the manufacturing that went overseas. Going further, when US firms look at the scenario (albeit a few years down the line) and see that the assets created overseas for manufacturing whatever widgets were outsourced have depreciated or is in need of upgrades to remain viable, that would be the decision point for deciding where the next generation of manufacturing will be located.

Much of the trajectory of what we see taking place goes to answering that question of the future and the above two agencies are hell bent on creating conditions that answer this question of manufacturing in the positive.

Or so I believe.

In such a scenario, what I believe to be key to long term competitive manufacturing is the ability to be smart about manufacturing – it means being able to operate using a very thin buffer for error because American firms will be competing with overseas firms (firm benefiting from their own countries’ competitive devaluation) that will continue to compete on large volumes and scale.

So what is Smarter Manufacturing?